Even though smart glasses for industrial applications are still not concrete enough, what we saw in 2013 reveals an opportunity. How can we allow the senior staff to be present virtually and offer effective consultation, assistance, or reminder to the junior staff? This idea constitutes the structure of the solution: using smart glasses as an interface for human interaction.

Reducing human errors AIR system improves the sustainable efficiency of offshore wind O&M_Interview withKevin Su, General Manager of ADAT technology corp.

Reducing human errors AIR system improves the sustainable efficiency of offshore wind O&M_Interview withKevin Su, General Manager of ADAT technology corp.

Kevin Su, General Manager of ADAT technology corp.

Kevin Su, General Manager of ADAT technology corp.

By Xin-En Wu

Adat Technology Co., Ltd. (Adat Technology) was established in October 2017 when an opportunity presented itself. "As the parent company of Adat Technology, Marketech International Corp. (MIC) has long been developing in the semiconductor industry, specializing in the original equipment manufacturing (OEM) or R&D for important modules of Type-A prime materials," General Manager of Adat Technology, Kevin Su implied. "The semiconductor industry requires highly specialized division of labor and process management of the production line. However, solutions for certain problems were not found, and the overall production cost was unable to remain under control. Until 2017, one particular problem had not been eliminated, which is the problem of errors caused by human factors."

AI Developing: Reducing errors caused by human factors

Su explained that human beings are organisms that operate in a pattern of "work as the sun rises and rest with the sunset," where 24/7 operation is impossible to achieve. In fact, human performance is often far from ideal at night. Under inferior conditions, human errors are prone to occur. In the past, the semiconductor industry lacked the proper tools to solve this problem.

"MIC and I both have practical experience in the semiconductor field. I personally have experience in processing equipment for over a decade, which allows me to quickly identify which difficulties need to be overcome and develop a solution through analysis. The production line operators usually carry out the equipment processing alone, but is the one-man model the most ideal one? Not really," Su noted. "According to the analyses, a one-plus-one model, which is one senior staff paired with a less experienced junior staff, leads to the best results. However, it is impossible to have that many senior staff available in the company to facilitate such a deployment, which leads to an outstanding idea: When one junior staff is conducting equipment maintenance, diagnosis, or installation, is it possible to provide 'expert support' as if it's giving by senior staff?"

In 2013, machine learning technology made a giant leap, with one of the most significant trends being the development and application of smart glasses.

"Of course, smart glasses for industrial applications are still not a concrete idea. Nonetheless, what we saw in 2013 reveals an opportunity, and we started to consider using structural solutions to tackle human errors and insufficient deployment," Su explained. "Under the cooperative team of one-plus-one, how can we allow the senior staff to be present virtually and offer effective consultation, assistance, or reminder to the junior staff? This idea constitutes the structure of the solution: using smart glasses as an interface for human interaction."

This method allows the knowledge and experience of the senior and junior staff to be exchanged through interacting with the smart glasses. But how can this idea be facilitated? Artificial intelligence (AI) is the answer, as the skills and tricks of the senior staff can be converted into the form of an APP. Experts can intelligently distribute their experience regularly, while junior staff can have instant access to such knowledge through the APP as needed without the physical presence of the senior experts.

Su mentioned that the configuration of smart glasses on the market was not fully mature at first, and there were only limited options. In order to verify whether the concept of "one-plusone" is feasible, his company proceeded to undertake a series of experiments, verifying and comparing the smart glasses available on the market at the time.

"Back then, we noticed that most smart glasses came with some core functions, but they are still insufficient in certain important aspects for industrial application. Nevertheless, such obstacles didn't stop us from moving forward, since we have established the cornerstone of this idea as we discovered more potential," Su noted. "The concept of smart glasses had evolved from what was previously unimaginable or unrealizable, to a possibility. The only question that remained was who would take on the role of developing the AI and AR systems suitable for industrial fields."

The advent of the AIR system

"In 2018, we successfully developed such technology. As the first software platform supplier in the semiconductor field, we were not complacent by providing the AIR system only, we made it an APP: the AIR APP system. Eventually, it still requires contributions by experts who are familiar with the field." Su explained. "What we did is exhibiting the feasibility of the AIR APP to the experts, as well as the significant value that can be produced in operating and maintaining the high-value equipment of the industry. However, to widely implement the AIR APP, a software platform is required. This is where Adat Technology comes in."

Adat Technology has developed a software platform called AIR Design Builder. For human errors to be eliminated or even prevented in the first place, a software development platform is essential. "Such a software development platform requires the ability to integrate AR, AI, and 5G altogether. Not many suppliers in the world are capable of doing this, as for local suppliers in Taiwan, only less than ten can be named with that ability." Su implied.

The suppliers who endeavor the development of smart glasses mostly come from the IT industry, while the designs of smart glasses are majorly for gaming purposes. Regardless of the supportive software or even the platform, most of them are still aiming at the gaming market.

"The requirements for gaming are substantially different from applications of various industries, and the industry could now only make use of the relatively acceptable option. We've also been observing which company might be the first to develop industrial glasses designed for the industry's needs," Su said. "Along with our software platform operated by the experts, such impeccable mechanism can be extensively applied throughout the entire industry."

Customized development and design

When it comes to product development, Adat Technology is characterized by the expertise of its key members with abundant practical experience from the industry. The concept that Adat Technology holds is unique, that is to establish a team in response to the needs of clients, instead of just developing certain IT technologies. The difference between the two is significant.

"I found many software companies proceed their developments with IT-oriented goals, which may distance themselves from the demand end. Since our key members have experience in the field, we can communicate with clients from the industry swiftly. We recognize their jargons, we know what their daily operations are like, and we understand all their problems and sufferings," Su noted. "With knowledge and empathy, we engage our clients through staff with experience in related fields, quickly tapping into their needs and pains, which actually helps to solve the hardest challenge in the process of developing any products: concreting and analyzing the client's needs, and eventually offering an effective solution for the client. Our ultimate goal is to provide a solution with the minimum cost and the maximum benefit."

Su pointed out that the most critical part is to truly understand what the industry wants or to even discover what it really needs. Professional IT engineers mastered programming languages and various software programs, which however does not guarantee their domain knowledge, not to mention the diversity of each client and each industry. The culture, characteristics, and commonly used approaches in all industries can be very different. Attempting to cover all the inconsistent characteristics with one consistent IT method can be tremendously challenging.

"Our strategy is sending experienced employees to explore and analyze problems of the industry and find commonalities. Most of our staff have engineering backgrounds, allowing us to always plan out a structure ahead to tackle the problem in the most effective way before designing the solution, which is delivered through the software platform end product," Su stated. "Instead of adding excessive fancy features, we follow the 80/20 rule, meaning we focus on the 20% functions that are the most critical to the client's operations, which will contribute to 80% of the performance. Our solution for our clients is always fully problem-oriented.

AI helps to "Store" the First-class Experience of Wind Farm O&M.

When it comes to wind farm operation and maintenance, several qualifications are required for the personnel responsible for the maintenance of offshore wind farms, including DP, GWO BTT/ BST, etc. "Currently, all suppliers involved are foreign companies. Apart from being familiar with their operating procedures, English comprehension is also required for workers," Su emphasized. "Although the localization of knowledge for wind power will eventually be carried out in the future, the purpose of this industry is not merely for economic growth, but also sustainable development. We are certainly anticipating the industry to improve its efficiency on wind farm operations and maintenance.

Su pointed out the three most common issues encountered in operation and maintenance projects, namely: on-board vessel operations, high-altitude operations, and familiarity with maintenance operations, which are the challenges every worker in the field faces. For Asian countries, however, additional problems emerge as English is usually not the native language. Moreover, young Taiwanese professionals' first choice usually lies in the prosperous semiconductor electronics industry that offers a steady career, fixed work hours, and handsome salaries.

"Let's compare that with the wind power industry. First, physical fitness is essential and seasickness must not occur. Second, climbing is the norm, and scare of height is unacceptable. Third, one must professionally keep the maintenance SOPs in mind, where English proficiency can be crucial. Why wouldn't a person with the above three traits pick a semiconductor or electronics company instead?" Su noted. "The fact is that wind power industry is much less attractive for job seekers, which leads to the next question: do we have to always introduce foreign experts on a large scale to support Taiwan's wind farm operation and maintenance? Due to the high cost, this is neither a plausible solution. Moreover, even for foreign companies, these professionals are also their scarce assets. It is impossible to fly so many foreign professionals to Taiwan all the time to conduct the work on a large scale. However, such a situation actually presents an opportunity." Su believes that a solution may be a game-changer if it enables wind power suppliers to ease staff insufficiency while delivering quality services, through achieving the three conditions mentioned above.

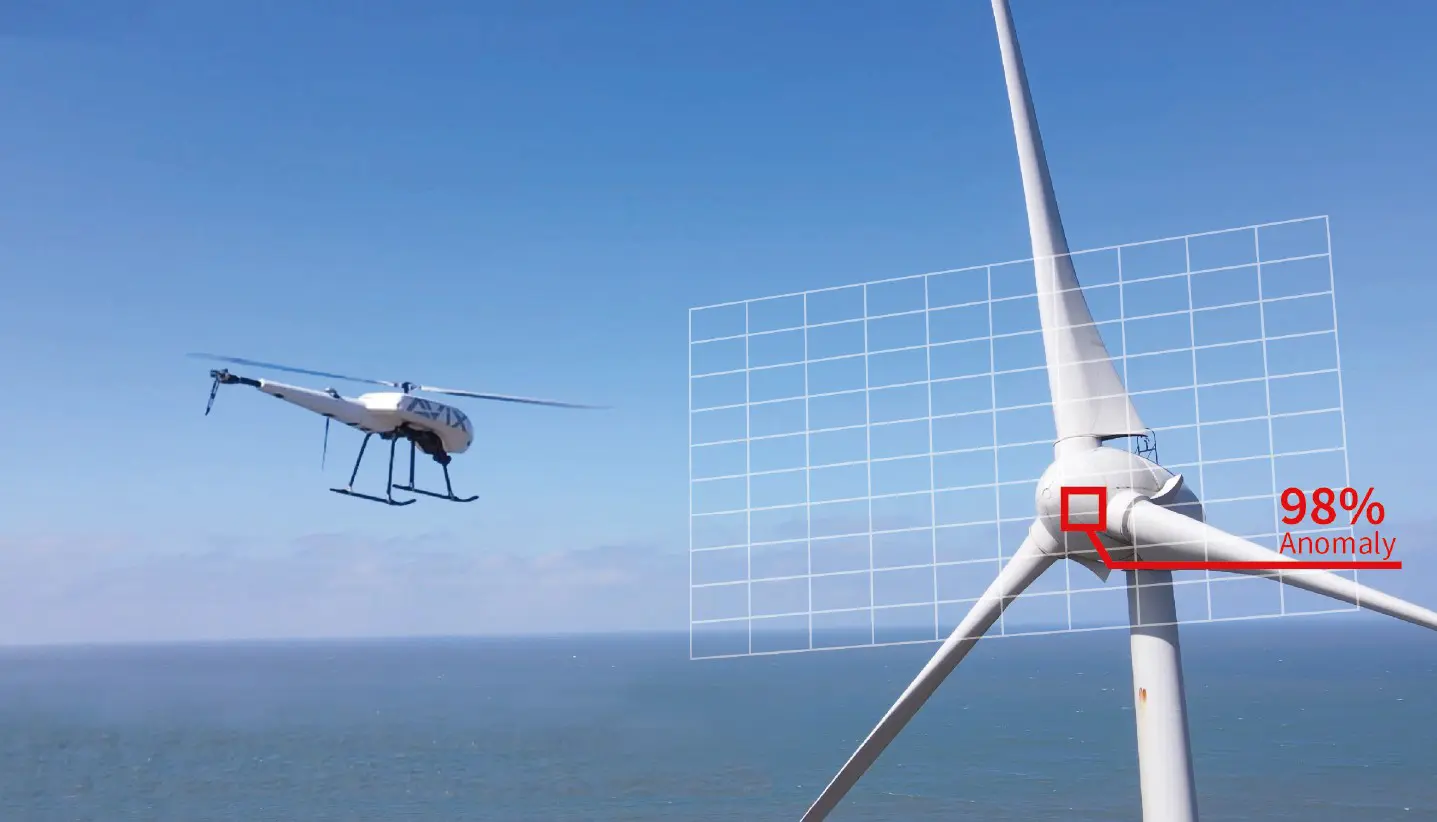

"Talents are prone to choose a more friendly environment, but not everyone ends up working for a semiconductor or electronics company. Regarding the three requirements for the operation and maintenance of the wind power, maybe the new recruits can meet only two out of the three requirements, like someone strong, suffer no seasick, and operates well at heights, yet fail to possess a decent English proficiency or machine repairing skills. These shortcomings may require a heavy load of transplantation of logical structure, which is where the AIR system shines the most," Su noted. "The recruits can pass the test only for the first and second requirements, as the AIR will support them for the rest. Through the guidance provided in their native language, the properly designed UI and UX, and the clearly-specified icon presentations, the recruits can finish the task in one shot without error, and it's even performed with the quality checked."

Suppliers in charge of development and operation & maintenance services in the wind power industry may have to accept that it is unnecessary to set the bars for hiring so high. With the assistance of the AI system, suppliers will obtain sufficient team members, technologies, and qualifications required for the operation and maintenance of wind power projects. If such a model finds success in Taiwan, then when it is applied to other regions under wind power development, e.g. Vietnam or South Korea, similar issues encountered in Taiwan such as personnel quality, shortage of laborers, language barrier, etc., can all be overcome through AI technology. The AI will at least help the staff to meet certain standards, which enables the suppliers to hire with less demanding terms, which means more recruit options will be available.

"In addition, there's one more critical advantage worth mentioning: in recent years, Taiwan has just initiated wind power introduction on such a large scale. It is unreasonable to maintain the conventional way with operation and maintenance. This is where the phenomenon of the 'late comer's advantage' should be reminded, as the most effective and advanced technology currently can always be adopted to complete the task," Su emphasized. "Assuming that Taiwan has no prior experience in building railways until this point, if we start right now, shall we pick the steam locomotive? Probably not. Instead, we would consider building the latest high-speed rail from the onset, and the reason is obvious. Almost every person would choose this way."

Likewise, the same logic applies to the wind power industry in Taiwan. "We are currently building wind farms on large scales. Naturally, we should apply the most effective technology available at current times. The application process still requires verification and testing. However, since we are a local development team, the gap in knowledge exchange and communication can be minimized, which also constitutes a dominant advantage for operation and maintenance suppliers," Su stated. "The finest advantage Taiwan owns is its clusters of high-tech enterprises in the semiconductor and AI industries. As we incorporate AI into the development and operation and maintenance of wind farms, the software and the hardware structure can be formed or produced locally in one stop, which is truly amazing. This will allow Taiwan to play an even more important role in the eco-system of the entire wind power industry."

Although most of the core design and construction technologies of the wind farm projects in Taiwan are currently provided by foreign suppliers, Taiwan still poses itself in an advantageous position thanks to its solid IT and 3C industry backgrounds. These industries don't necessarily have to struggle with the present wind power industry supply chain, instead, more values can be added.

The RPRP Principle: Right People in The Right Position

"I major in aeronautics and astronautics from my undergraduate and graduate studies, I had also intended to pursue a career in such fields back then. However, when I entered the job market in 2000, the aeronautics and astronautics industry was suffering from dire market conditions, which leads to scarce job opportunities. At that time, most of the jobs available in Taiwan were from the semiconductor industry; so by fate or by accident, I started working for ASML. At first, I was an equipment engineer, I was later promoted to a management position, and once the Supervisor of the Global Education Training Center," Su recalled. "Such experience allows me to understand one very important fact; that is, in the industry, the cores of many things are actually quite similar, which contains factors no other than logic, physics, engineering, and human nature. Once these factors are properly managed, most problems can be avoided in advance. At Adat Technology, the RPRP principle is highly stressed, that is, putting the "Right People in the Right Position". I also found that the "Peter Principle" is rather common in many companies."

The Peter Principle refers to a theory that people in an organization tend to end up being promoted to a high position where they are incompetent of fulfilling their responsibility. "We realized then that the only solution was the 'RPRP' principle: Putting a wrong person, especially, in leadership positions, harms not only the appointed person but also all the people under such management. The cost for not following RPRP is always tremendous," Su explained.

Su believes that organizations should try their best to identify each person's strengths before hiring them, and to fully utilize people's strengths to the maximum. In this way, management and communication costs can be minimized, while employees can also make contributions from what they are best at, thus forming a virtuous circle. When people are doing what they are best at, the sense of achievement and belonging can be easily fostered.

Su thinks that a good manager does not need to drive employees with stress. Rather, the most important task of a manager is to determine the right direction while providing necessary resources and assistance as needed.

By all means, it is hard to define each person's specialty, which has been discussed for decades in the management field. This is why human resource and organizational management have always been such prominent subjects in management science. Especially in Taiwan, as various industries face a severe scarcity of workers, it certainly won't be easier to recruit talents perfectly matching the company's business models while they are allowed to utilize their full strengths.

"This is why I firmly believe in AI's advantage in this field. Whatever method works, we shall adopt accordingly. After all, the clients, the company, or the employees themselves will be the ones benefiting the most from the right choices," Su noted. "Effective methods will provide the same results with fewer working hours, offering more time for self-improvement and enjoying our lives. I believe that is what we've all been striving to achieve."

More related articles